Outcome

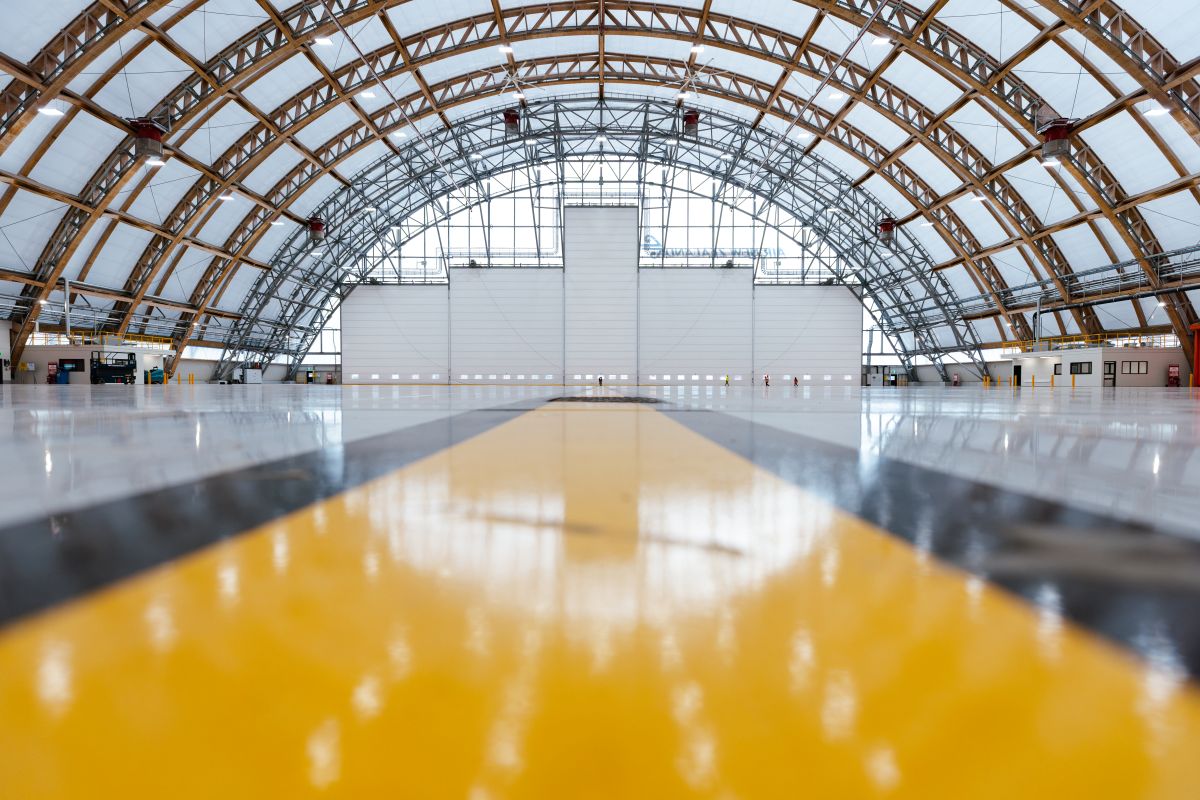

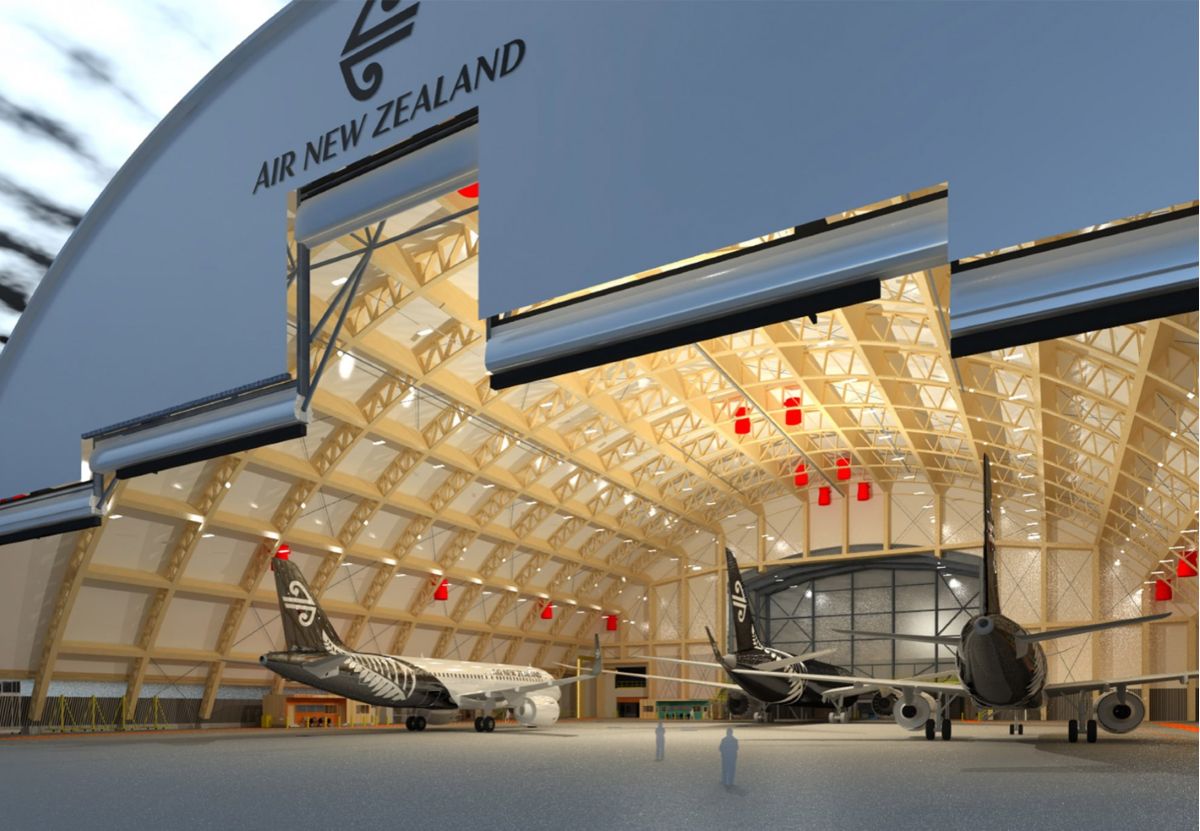

Hangar 4 is a world-first in mass timber aviation infrastructure, showcasing how precision engineering and collaborative problem-solving can overcome the challenges of scale and complexity. XLAM’s solutions ensured that all 7,141 individual timber components could be prefabricated, transported, and installed safely and accurately. Each truss used 12,500 screws, totalling 250,000 across the project, reflecting the precision and quality control required for such a landmark structure.

The DfMA approach, combined with close collaboration with Engineers, Dunning Thornton, allowed every connection, hinge, and purlin to fit perfectly on-site. Hinge connectors at the base of the trusses enabled them to twist and move during lifting, improving safety by preventing uncontrolled swinging in high winds. Even with pandemic delays and evolving design codes over the seven-year delivery, the project was completed on schedule and without liquidated damages, demonstrating the effectiveness of XLAM’s integrated design, manufacturing, and logistical solutions.

Hangar 4 serves as a statement of intent: it proves that timber can deliver the performance and scale required for world-class aviation infrastructure. The timber structure also offers remarkable earthquake performance and sustainability credentials.